KC PANELS (KCP) has been dedicated in aluminum honeycomb products for more than 15 years. We are one of the few manufacturers in China that provides comprehensive lightweight honeycomb solutions, ranging from aluminum honeycomb core, aluminum honeycomb panels to stone honeycomb panels.

KCP understands international standard. By participating in landmark projects all over the world, we have gained ample experience and know-how to meet with the most stringent standards in the industry. We have in-depth cooperation with renowned adhesive manufacturers to ensure that our honeycomb core panels can endure the most extreme using conditions, interiorly or exteriorly.

KCP cares about quality. We fully implement ISO 9001 at every production sector in the factory. Experienced QC staffs are assigned to each individual project to tackle possible defects and issues throughout the whole processing. In-house laboratory carries out vital testing on randomly selected specimens during production to monitor the bonding performances.

KCP got capacity. We have a 20,000M2 workshop with high-efficient machineries and production lines. Annual output for aluminum honeycomb core 500,000M2; aluminum honeycomb panels 200,000M2; stone honeycomb panels 100,000M2. Our key workers all have more than 8 years in manufacturing ACM metal panels which enables punctual delivery with high quality.

KCP makes good offers. We have good resources for raw aluminum and stone quarries locally and internationally. We integrates production from aluminum honeycomb core to aluminum honeycomb panels and stone panels which reduces outsourcing and effectively lower the cost. Our team is simple in structure but high in executive efficiency. All of which enable us to make competitive offers on quality-assured ACM honeycomb panels.

Contact us today to get estimates on your projects.

Read More

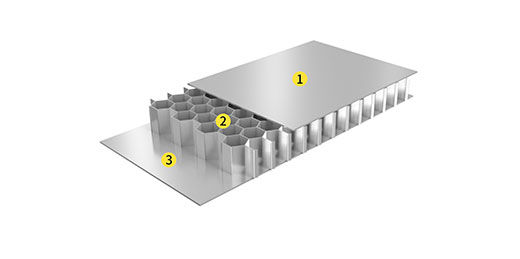

KCP’s aluminum honeycomb panels is a sandwich structure consists of two layers of aluminum sheets and aluminum honeycomb core in between. These three layers are bonded by epoxy thermoplastic films. The layers and the films are hot pressed under temperature around 150 degree Celsius to form the finished aluminum honeycomb panels. With the characteristic of elastic and weather resistant, our film-bonded aluminum honeycomb panels can be used under most extreme weather conditions ranging from -40 degree to 80 degree Celsius.

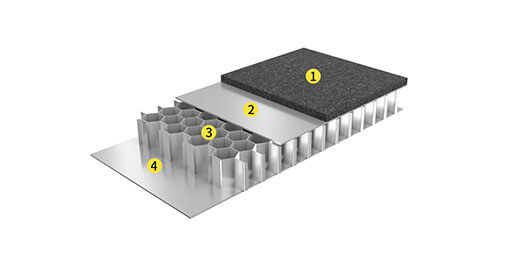

KCP’s stone honeycomb panels consist of 6mm natural stone veneer or 3mm porcelain slab on top and aluminum honeycomb panels as backing for reinforcement. The top veneer is bonded with the backing by specifically developed epoxy adhesive. KCP works closely with internationally renowned adhesive brands to ensure that the glue applied on each individual stone panel fits for the use in even the most extreme conditions. For example, our stone honeycomb panel can endure vast temperature changes from -40 degree to 80 degree Celsius while the bonding strength stays at excellent level after decades.

View our project portfolio from all over the world, interior and exterior. Click on the image for more details.

View All