Aluminum honeycomb core were firstly applied in aerospace industry several decades ago. It is a very strong structure made from soft and relatively low-price material to achieve best cost efficiency. The aerospace-grade epoxy adhesive is applied uniformly onto aluminum foil in designated order and frequency by machine, and the foils will be stacked and hot pressed to form a block. Honeycomb slices will then be cut from the block and after fully expanded, the aluminum honeycomb core is made.

KCP offers two ranges of aluminum honeycomb core categorized by its cell size – micron-aperture aluminum honeycomb core and regular aluminum honeycomb core. By definition, cell sizes that are equivalent or under 1/5” is called micro-aperture core, which are used for lighting, machinery, filter etc. While for the cell sizes that are above 1/5” is called regular core, which is ideal for uses of construction, interior fit-out, transportation, marine, etc.

According to different applications, KCP offers below category for aluminum honeycomb core:

The aluminum honeycomb core is one of the best options for core material of ACM metal panels and honeycomb aluminum sheets. Its lightweight feature and high rigidity also makes it to be widely applied in many other applications.

Talk to us today to find out the best solution for you.

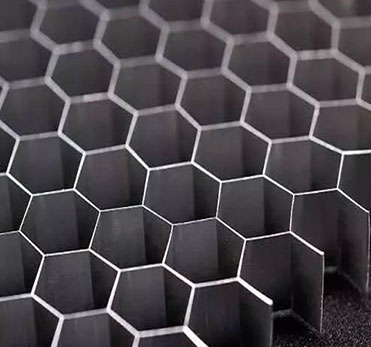

Aluminum honeycomb core is an array of hexagonal hollow cells formed between thin vertical aluminum foil. It has the geometry of honeycomb with purpose of achieving highest strength-to-weight ratio. It has been widely used in aerospace industry since 1950s and later on being introduced to the building sector for lightweight and large-format composites material.

Cell Size Definition:

a=Grid length

b=Inner circle diameter

c=Thickness of aluminum foil

Let’s delve deeper into the engineering nuances that make aluminum honeycomb cores extraordinarily robust.

Aside from using aerospace-grade epoxy adhesive to ensure the core’s structural integrity, we also have strict quality control processes in place to ensure the flawless application of the adhesive onto the aluminum foil. Here at KCP, we use state-of-the-art machinery to meticulously control the frequency, placement, and thickness of the adhesive, guaranteeing a consistent bond throughout the core. This uniformity is a cornerstone of the core’s resilience and structural integrity.

Equally noteworthy is the precision with which the honeycomb slices are cut from the hot-pressed block. Advanced laser cutting technology is employed to ensure that the cellular structure remains perfectly aligned and intact, reducing any chances of internal stress or weak points that might compromise the core’s performance.

KCP offers two main types of cell sizes in its aluminum honeycomb cores: micron-aperture and regular. The micron-aperture cores have smaller cell sizes of 1/5″ or less, while the regular cores have larger cell sizes exceeding 1/5″. This selection allows the cores to be customized for various applications and specific mechanical needs.

You can choose from three different forms of aluminum honeycomb core: raw blocks, slices that haven’t yet been expanded, and fully expanded cores. This range of options gives you the flexibility to pick the form that best suits your project.

Structurally, the aluminum honeycomb core is made up of a series of hexagonal hollow cells. These are formed between thin layers of vertical aluminum foil. An aerospace-grade epoxy adhesive is used to bond these cells securely, creating a strong and durable structure.

The thickness of the aluminum foil and the shape of the honeycomb cells can be adjusted based on the project’s needs. For the best results, it’s advisable to consult with KCP to explore the available options for thickness and cell geometry.

Beyond aerospace and construction, the advantages of KCP’s aluminum honeycomb panels extend to various other sectors.

KCP’s aluminum honeycomb cores offer not just exceptional mechanical properties but also a high degree of versatility, opening up a wide range of application possibilities. You can count on their ability to stand up to the challenges of the modern world.