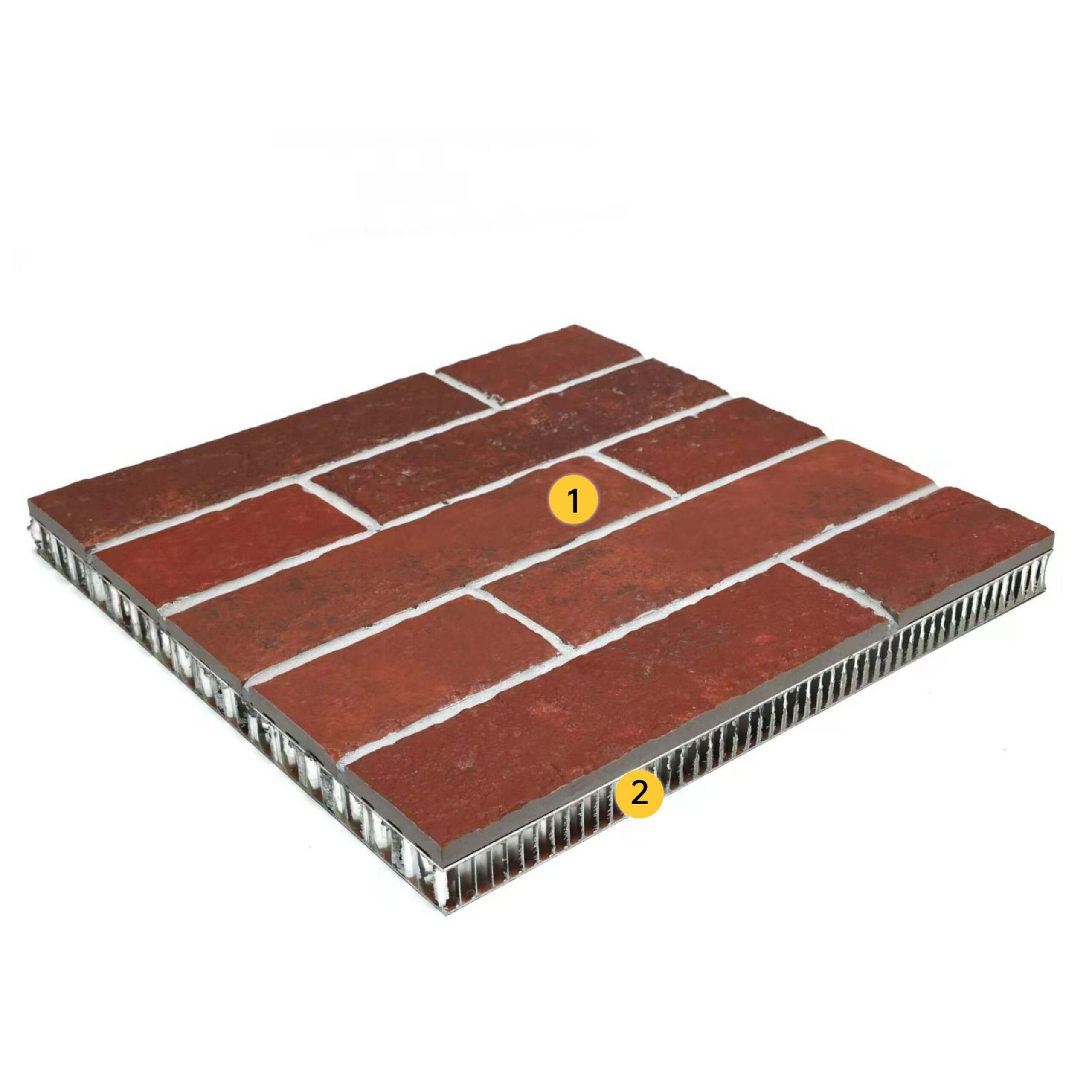

KCP’s brick honeycomb panels aim to turn traditional brick works into modular installation.

By applying brick-alike porcelain tiles on top of one-piece aluminum honeycomb backing, our brick honeycomb panels preserve the beauty of traditional brick works, and at the same time providing key advantages say lightweight, fast and low-cost installation, longevity, dry installing, etc.

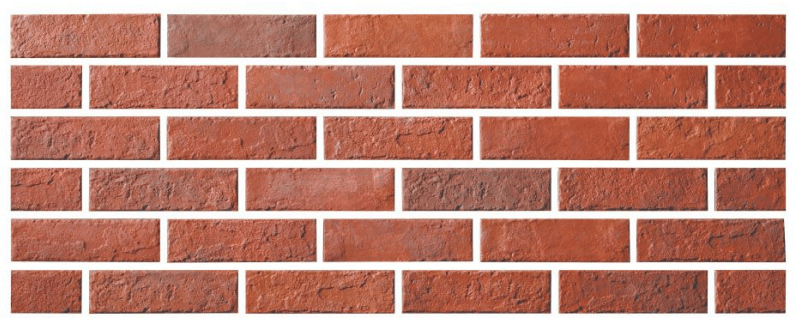

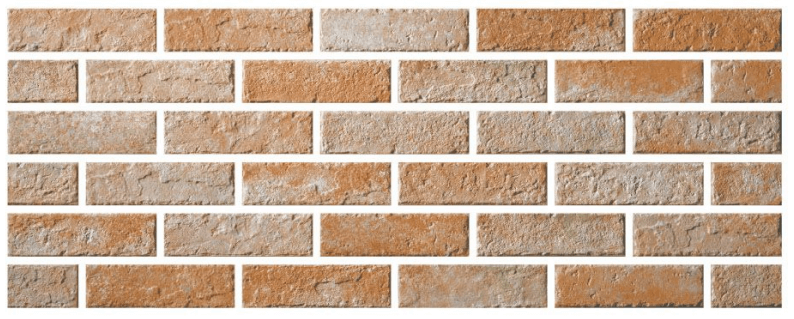

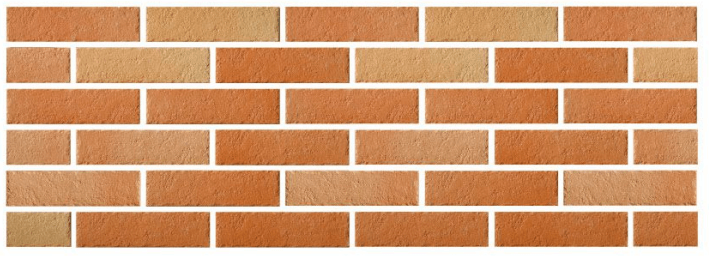

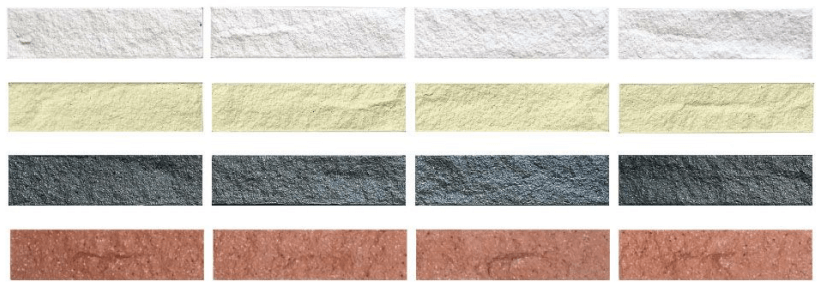

A wide variety of brick selection is available, from contemporary design to the most traditional aesthetics. Some of the patterns are produced with antique looking with on-purpose color variation so to provide nearly the same looking from the real bricks.

The brick tile is 9~10mm thick and will be laminated onto the aluminum honeycomb panels in factory, according to the required layout approved by customers. Grouting will be also completed on each panel in the factory, to save as much as excessive works from jobsite – All needed to be done is to hang the panels with interlocking systems which is easy and neat.

Typical size of the brick cladding panels is 1220*2440mm, or 1500*3000mm and is customizable. Pre-fabrication is also available according to production drawings. The panels can be cut-to-size and assembly with returns to suit every elevation precisely.

Leave all the complicated and time-costing works to us and you just care about the installation.

KCP’s brick honeycomb panels consist of 9~10mm brick-alike porcelain tiles on top and aluminum honeycomb panels as backing for reinforcement. The top veneer is bonded with the backing by specifically developed epoxy adhesive. KCP works closely with internationally renowned adhesive brands to ensure that the glue applied on each individual brick honeycomb panel fits for the use in even the most extreme conditions. For example, our brick panel can endure vast temperature changes from -40 degree to 80 degree Celsius while the bonding strength stays at excellent level after decades.

The bonding is always the most pivotal concern for brick cladding panels, especially for exterior applications. KCP only applied adhesive from proven brands which have at least 20 years of experience in the honeycomb composites field. Such adhesive is wildly used in honeycomb projects around the world for decades. KCP also deeply cooperate with adhesive suppliers and follow strictly with their guidelines of proper applications. The storage room with constant temperature control is built for adhesive storing; Dust-free glue blending room is also built for two-component blending for lamination. Our panels can reach 1.5MPa for tensile test and lasts for over 100 years with acceptable degradation.

Over 60 types of brick patterns is available to suit for different design intents, from contemporary design to traditional looking, from light colors to dark colors. The surface can be made into smooth or textured.

Contact us for completed pattern design of the brick tiles.

KCP provides solution of easy installation of the brick cladding panels.

The interlocking system uses G-shape interlocking channels. The brackets will be screw-fixed or rivet-fixed onto the back of honeycomb panels. While the channels will be pre-installed at jobsite to concrete wall.

After hanging the panels, fix the screws on the top row of channels. Align the panels by adjustment screw on top of the bracket.