Elevate Aesthetics and Strength with Aluminum Honeycomb Panels

Modern buildings with innovative architectural designs increasingly require superior construction materials to match their complexity and artistic vision. This rising demand for quality and precision in building materials leads builders and architects to seek specialized expertise. KC Panels is renowned for meeting these advanced requirements with custom-made aluminum honeycomb panels.

At KC Panels, we utilize advanced technology and innovative solutions to assist our clients in realizing their architectural visions. Our aluminum honeycomb panels are designed to enhance a building’s appearance, thermal efficiency, and energy performance. We also provide specialized services in fabricating, planning, and installing these panels, ensuring they deliver maximum performance and durability.

Continue reading to learn about the advantages of aluminum honeycomb panels and how they can strengthen and beautify a building.

What are honeycomb aluminum panels?

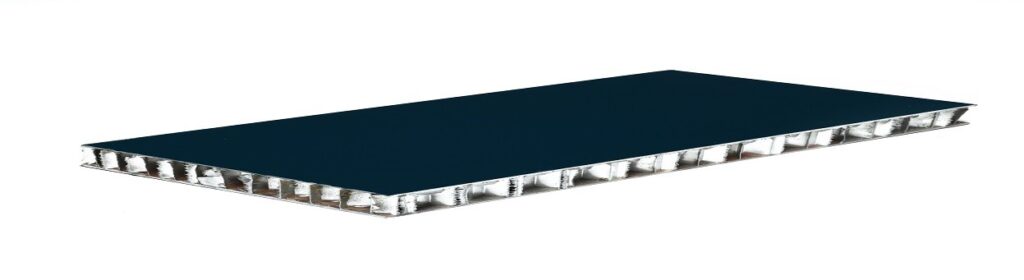

An aluminum honeycomb panel has a unique composition that consists of an aluminum honeycomb core sandwiched between double layers of aluminum sheets. A special thermoplastic adhesive bonds these components to keep them in place and create a solid composite panel.

Aluminum is an excellent material for making custom aluminum honeycomb panels because of its high thermal performance and tensile strength. Plus, its aesthetics are unmatched by other lightweight metals. With honeycomb core technology, aluminum becomes exceptionally long-lasting and durable for the most demanding applications while remaining cost-effective.

A versatile building material

Besides possessing high strength and low-weight features, a honeycomb aluminum panel is customizable in any size and with specific adhesives to make it suitable for any application. Our panels have been used in many different projects under different scenarios, such as marine, transportation, cladding, flooring, and ceiling. We apply various treatments to make each panel more unique and capable of meeting aesthetic requirements, offering powder coating, PVDF, heat transfer printing, PE, and more.

Another great thing about aluminum is it is easy to shape and form into specific geometries. At KC Panels, we have the technology and tools to deliver odd-shaped honeycomb aluminum panels, including 3D, 90-degree return, and curved. We are confident in our ability to supply high-quality materials to meet any design or architectural requirement.

Durable and strong materials

The manufacturing process can make a difference in the strength and aesthetics of aluminum honeycomb panels. At KC Panels, we bond all layers of aluminum sheets and the honeycomb core with epoxy thermoplastic films. These parts are hot-pressed under 150 degrees Celsius to create a secure and complete composite panel that is weather-resistant and elastic and withstands extreme temperatures from -40 to 80 degrees Celsius. Given these benefits, we guarantee robust and long-lasting materials to keep your structure standing and good-looking for many decades.

It’s in the bonding.

The adhesive is among the critical considerations when manufacturing a honeycomb aluminum panel. At KC Panels, we use specially formulated thermoplastic adhesive films to laminate the layers. The material is solid at room temperature but melts at 130 degrees Celsius.

Unlike regular epoxy, the thermoplastic film is more weather-resistant due to its high elasticity. As such, it moves with the substrate without failure, especially when exposed to rapid changes in temperature. In addition, it can withstand intense heat during hot summers.

Another benefit of thermoplastic films is their significant improvement in production efficiency when compared to epoxy. This way, we can deliver the panels to your construction site sooner and help you finish your project within the agreed timeline.

For special applications

For applications that require enhanced bonding strength, KC Panels manufactures aluminum honeycomb panels using modified epoxy with a patented epoxy-friendly coating. We coat aluminum sheets with the patented epoxy-friendly layer to improve bonding and tensile strength to over 50%. This way, our products become versatile for interior and exterior applications.

Select your panels

We offer our honeycomb aluminum panels in sizes of up to 2000mm wide and up to 6000 long, in thicknesses ranging from 5 mm to 500 mm. Moreover, we offer the following finishes for specific applications:

- PVDF coating

Polyvinylidene fluoride (PVDF) is a suitable paint for exterior aluminum sheets. We recommend this option for structures exposed to extreme weather and temperatures. As such, it’s ideal for exterior cladding, marine panels, mold panels, and roof panels. - PE coating

For indoor decorations, we recommend polyethylene (PE) paint to coat each honeycomb aluminum panel. This coat is also ideal for aluminum furniture, partitions, and ceilings. - Epoxy or anodizing coating

Anodizing aluminum keeps honeycomb sheet panels safe from oxidation. At KC Panels, we do this on the invisible side of the veneer or stone panel. Additionally, we offer epoxy-coating aluminum to prevent corrosion while enhancing the glue-bonding performance. This results in the honeycomb core’s pull strength becoming 2.0MPa, so the material becomes useful as backing for laminates using natural stone, veneer, porcelain, solar components, or wood. - Mill finish

Aluminum honeycomb panels can be laminated with other materials, like natural or engineered stone. For this, you can choose a mill finish to enhance their aesthetics without compromising weather and temperature resistance. - Heat transfer printing

KC Panels uses heat transfer printing technology to create patterns on the panel, such as stone veins and wood grain. This way, we can customize the panels for interior or exterior use and eliminate the need for natural materials. - Stainless and galvanized steel

Steel is great for exterior and interior applications requiring optimum fire performance without sacrificing aesthetics. We can fulfill this requirement by replacing the bottom and aluminum sheets with galvanized or stainless steel. Plus, we can finish the panels in different ways, including mirror, sanding, hairline, or etched, and in various colors.

Get the best materials for your project now.

Allow us to provide the best honeycomb aluminum panel for your next project. Our high-quality products bring the most comprehensive honeycomb solutions to enhance your structure’s quality and longevity. Get in touch with KC Panels today for a quote.

View All