As the leading manufacturer of honeycomb panels in China with 15 years of experience, KCP supplies aluminum honeycomb core, aluminum honeycomb panels and stone honeycomb panels for various applications. We always persist in our core value – top quality panels, punctual delivery, with good pricing. With 20,000M2 of production facility, we integrate production lines from the core the finished honeycomb panels, which enable us to control the cost, and more importantly, the quality. Throughout the years our aluminum honeycomb panels and stone honeycomb panels have been supplied to U.S, Canada, Australia and many others for landmark projects, which are the good proof that KCP achieves top standards. Click on below bottoms to learn more information about our aluminum honeycomb products.

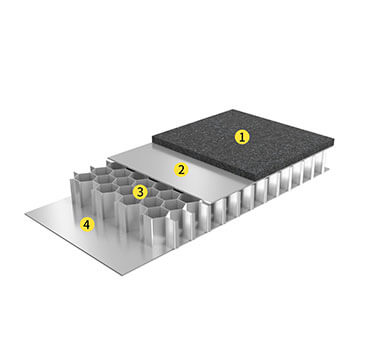

The typical aluminum honeycomb composites are made up of layers of aluminum sheets or fiberglass sheets and aluminum honeycomb core in between to form a sandwich structures. By bonding with designated adhesive, such sandwich structure is featured with ultra-lightweight and robust strength, which is an ideal composite material for cladding, flooring, ceiling and many more applications.

With the strong backing, thin layer of other high value but brittle decorative materials can be also bonded onto. For example, our stone honeycomb panels have a 6mm natural stone veneer bonded on top of the aluminum honeycomb panel backing. It inherits the natural beauty of stone, while significantly reduces the overall weight of stone cladding. Therefore the stone honeycomb panels are a ideal alternative for solid stone works which greatly reduces the project budgets while allowing for way faster installation at jobsite.

KCP’s products embody innovation, reliability, and unparalleled performance. Whether you are an architect, builder, or engineer, our meticulously designed honeycomb panels are tailored to meet your project’s most stringent requirements.

At the core of any honeycomb panel is its unique geometric configuration, resembling the structure of honeycombs found in beehives. This design is optimized for robustness, allowing for the high strength-to-weight ratio that these panels are known for.

The honeycomb structure also serves as a natural insulator and sound barrier, providing an extra layer of functionality beyond just structural strength.

The distinctive honeycomb core serves as the foundation for the panel’s unparalleled strength. The hexagonal cells distribute forces applied on the panel, effectively dissipating mechanical stress. This enables honeycomb panels to withstand high loads and impacts while remaining lightweight compared to traditional construction materials.

In practical terms, this means that honeycomb panels can be used in situations that demand both durability and efficiency. Whether it’s withstanding environmental stressors like wind loads in architectural applications or enduring high-speed impacts in aerospace, these panels are designed for extreme resilience.

KCP’s honeycomb panels are engineered with advanced adhesive technologies, ensuring that the bonding between the core and the surface layers withstand extreme conditions. We utilize specific adhesives that can withstand fluctuations in temperature and humidity, safeguarding the panels from delamination or material degradation over time.

One of the significant parameters affecting a honeycomb panel’s performance is the core thickness. Essentially, the stiffness of a panel increases exponentially with the thickness of the core, given that the material and design remain constant.

This allows for customization depending on the specific load-bearing requirements of your project. For example, a panel with a thicker core may be chosen for an aerospace application where high stiffness is needed, while a thinner core may be ideal for interior design elements that require less load-bearing capacity.

At KCP, we offer panels with varying core thicknesses tailored to specific applications ranging from aerospace to construction. Our engineering team is adept at optimizing core thickness to meet and exceed the functional and structural needs of your projects.

The versatility of honeycomb panels extends far beyond their core structure, finding applications across various industries:

– Reduce the dead loads on structures while maintaining aesthetic appeal, ideal for both new constructions and renovations.

– Use our panels to achieve high-end looks without compromising on strength or increasing weight, allowing for more design flexibility.

– In industries where weight is a critical factor, our panels offer the ideal combination of lightness and strength.

– Our fiberglass panels are well-suited for applications requiring resistance to corrosive environments.

– Utilized in wind blades and other renewable energy applications, our panels meet stringent requirements for strength and weight.

Explore our range of high-performance honeycomb core panels today. With KCP, you’re not just getting a product; you’re investing in materials that bring proven durability, aesthetic flexibility, and engineering prowess to your projects. Feel free to reach out to our team of experts to discuss your project’s specific needs.