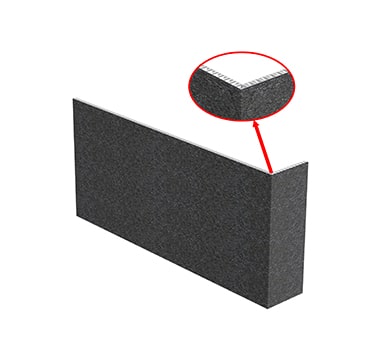

With aluminum honeycomb panels or fiberglass honeycomb panels as reinforcement, a 5mm stone veneer is bonded on top to keep the natural aesthetic beauty with ultra-lightweight and strong feature. This type of stone veneer panels with honeycomb reinforcement has a wide range from natural materials say marble, granite, limestone, sandstone, onyx, basalt, etc., to artificial materials say porcelain, ceramic, engineered stone, glass etc.

The stone honeycomb panel is an ideal choice for exterior cladding due to its ultra-lightweight feature. Comparing to thick solid stone slabs, the stone veneer panels for exterior with honeycomb structure usually weigh only 1/3 of the solid ones. The stone panels can significantly reduce dead load of the whole exterior façade, which can transfer into savings of millions of dollars. While due to large format and lightweight, installation can be also three times faster than the solid stone. It will contribute a great saving on installation cost and time.

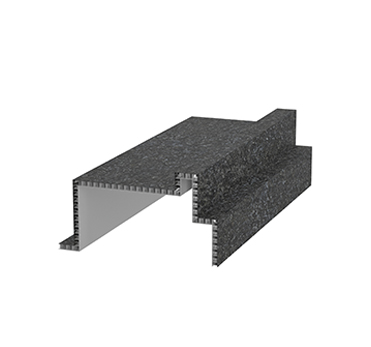

For the aspect of interior stone works, stone honeycomb panel is also a brilliant choice. High-value stone always gets specified by many upscale commercial and residential projects for the sense of luxury, therefore by applying stone honeycomb panels, the cost for stone slabs can be cut into half as one single slab can yield two stone honeycomb panels. While by applying stone panels, most of the fabrication works can be finished in the factory. On one hand, the fabrication quality will be way higher than doing at jobsite. On the other hand, it saves most of the excessive site works to save both time and money. KCP has rich experience of manufacturing stone honeycomb panels for both exterior and interior uses. We have landmark projects applying our panels in U.S, Canada, Australia and many major Chinese cities. Talk to us today for quality stone honeycomb panels with competitive pricing.

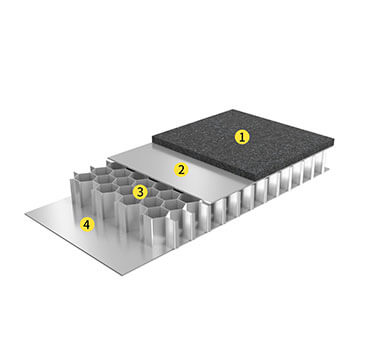

KCP’s stone honeycomb panels consist of 6mm natural stone veneer or 3mm porcelain slab on top and aluminum honeycomb panels as backing for reinforcement. The top veneer is bonded with the backing by specifically developed epoxy adhesive. KCP works closely with internationally renowned adhesive brands to ensure that the glue applied on each individual stone panel fits for the use in even the most extreme conditions. For example, our stone honeycomb panel can endure vast temperature changes from -40 degree to 80 degree Celsius while the bonding strength stays at excellent level after decades.

The bonding is always the most pivotal concern for stone honeycomb panels, especially for exterior applications. KCP only applied adhesive from proven brands which have at least 20 years of experience in the honeycomb composites field. Such adhesive is wildly used in honeycomb projects around the world for decades. KCP also deeply cooperate with adhesive suppliers and follow strictly with their guidelines of proper applications. The storage room with constant temperature control is built for adhesive storing; Dust-free glue blending room is also built for two component blending for lamination. Our panels can reach 2.0MPa for tensile test and lasts for over 100 years with acceptable degradation.

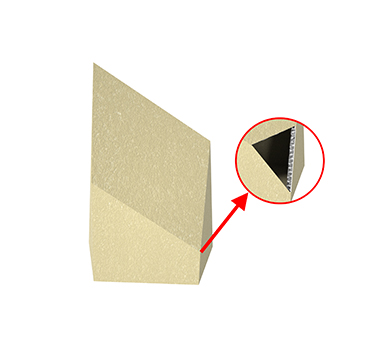

KCP has CAD drawing engineers who has honeycomb-related experience for over 10 years. With customers’ shop drawings, we will transfer them into our own production drawings with accuracy and precision. With the production drawings on hand, KCP also got a fabrication team with experienced workers for odd-shape panels, who have an average of 7-year experience in fabricating stone honeycomb panel. With such tight cooperation between two teams, KCP is good at fabrication for exterior panels, as well as complex odd-shape panels for interior fit-outs.

The innovative engineering behind our stone honeycomb panels sets them apart, making them a superior choice for any project that requires both aesthetic appeal and structural integrity. Let’s dive deeper into the unique features that contribute to their robust structure.

Beyond the stone veneer and the honeycomb backing, our panels incorporate additional layers to further enhance their durability. These include a UV-resistant coating and a water-resistant membrane that collectively protects against environmental wear and tear. These extra layers also contribute to the panels’ low-maintenance requirements, ensuring they remain visually appealing and structurally sound for years to come.

Due to our specially formulated epoxy adhesives, our stone honeycomb panels are highly resistant to moisture ingress, making them perfect for humid climates or areas exposed to rain and snow. Additionally, their temperature resistance allows them to retain their integrity even in extreme hot and cold conditions, making them suitable for use in various geographical locations.

Our stone honeycomb panels typically achieve a 66% weight reduction compared to traditional stone slabs, with average panel weights ranging from 15 to 20 kilograms per square meter, depending on the stone veneer used.

Given the crucial nature of fire safety in construction, our stone honeycomb panels are developed to meet stringent fire resistance standards. Each panel undergoes a series of tests to ensure it meets or exceeds local and international codes.

While standard panel dimensions are available, we offer customization down to millimeter-level precision for projects with specific requirements. This allows our panels to adapt to intricate designs or unique structural needs, including curves and non-rectangular shapes.

Beyond the more general applications mentioned, the unique qualities of our stone honeycomb panels offer several advantages across a range of specialized uses.

Our panels are an excellent choice for retrofitting existing structures. Their lightweight nature drastically reduces the load on the existing building, making it possible to add new cladding or features without compromising structural integrity.

Our lightweight panels can result in substantial cost savings in material, labor, and time. Their lighter weight allows for quicker installation and less reliance on heavy-duty cranes, accelerating overall project timelines.

Our stone honeycomb panels are often selected for high-end residential projects due to their luxurious appearance and long-lasting durability. The ability to customize the stone veneer enables architects and designers to realize unique aesthetic visions while enjoying the functional benefits of the honeycomb structure.

Given their resistance to moisture and microbial growth, our panels are also ideally suited for environments that require stringent hygiene standards, such as hospitals or laboratories.

Whether used in airports, train stations, or marine terminals, our panels can handle the high foot traffic and mechanical wear typical of these environments. Their inherent strength and resilience make them a practical yet visually pleasing option for large-scale public spaces.